Manufacturing has always been a business of tight margins. However, globalization means competition is fiercer than ever, while supply chain complexity and rising materials costs in the last few years have caused additional unwanted complexity. Throw on top of that an ever-evolving regulatory landscape, and it’s clear that RPA automation in the manufacturing industry is more vital than ever.

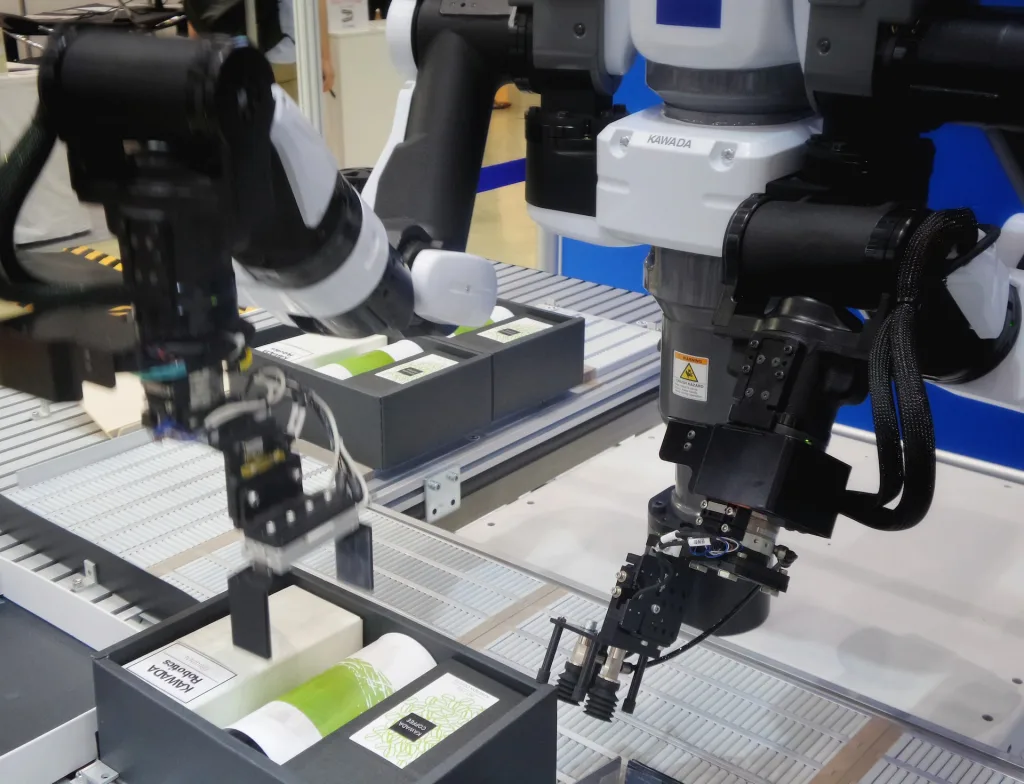

Factory RPA automation can improve operations, employee satisfaction, and profits. It can also support an organization on every level, from internal management and communication right through to supply chain optimization and quality control. Manufacturing and automation have gone hand in hand for almost a century. RPA represents the next step in this symbiotic relationship.

In this article, we’ll explore RPA automation in the manufacturing industry and look at use cases, case studies, benefits, challenges, and future applications.

Manufacturing and automation: long-time friends

Manufacturing and automation have been bedfellows since the 20th century. Automation machinery manufacturing on factory floors has made for some of the most compelling and value-driving uses of robotics because of their speed, precision, and cost-efficiency. However, when it comes to back-office administrative tasks, manufacturing teams have been a little slower on the uptake.

Manufacturers’ widespread adoption of physical robotics underlines the industry’s openness to new tech. The sector’s embrace of mechanized production tools was driven by a desire to compete. With tight margins and global competition forcing manufacturers to find new ways to drive revenues, back and front-office tasks will become the logical next frontier.

Manufacturing and Factory RPA

automation market size

The global RPA market size currently stands at around $13 million. However, with a huge compound annual growth rate of 33%, the industry will grow to almost $100m by 2032

An ImpactMyBiz study from 2022 shows that over 4 in 10 manufacturing teams currently use

RPA in their business. The same amount plans to adopt these tools over the next few years. These numbers clearly demonstrate the appetite within the manufacturing space for automated solutions while also showing that there is still potential for early adopters to outmuscle competitors.

Why the manufacturing sector needs RPA

The manufacturing sector has faced considerable difficulties over the last few years. COVID-19 stay-at-home orders caused serious supply chain disruptions, and the resulting inflation ramped up materials costs. In addition, the conflict in Ukraine has manifested in rising fuel costs and semiconductor shortages.

Aside from these macroeconomic woes, the manufacturing industry faces a number of challenges over the next few years. Some of these big issues include:

1. Lack of skilled labor:

Manufacturing teams are dealing with talent acquisition problems as skilled workers retire or rotate to different sectors.

2. Shifting consumer preferences:

Product trends are constantly changing. In recent years, consumers have begun to demand more sustainability and ethical practices in manufacturing.

3. Globalization:

Technology and communication tools have opened the door to wider markets, but they have resulted in more competition, too.

4. Rising overheads:

Raw materials, energy, and labor costs have escalated, meaning profits are harder to achieve.

5. Increased regulatory scrutiny:

Governments around the world are enforcing stricter regulations on goods, with tight restrictions on various parts and practices.

The unique sets of challenges do not have simple fixes. However, RPA can help address each problem and provide a pathway towards solutions that benefit production automation teams.

RPA automation in the manufacturing

industry: Use cases

RPA can provide endless benefits for the manufacturing sector. Here is a taste of some of the use cases.

#1. Automating the Bill of Materials

The Bill of Materials is an important document that highlights what parts need to be manufactured. It’s critical that it’s always up-to-date and free of error. Manually handling the Bill of Materials is subject to human error, which can result in delays and costly mistakes.

RPA technology allows for real-time management of the Bill of Materials. It ensures that everyone is on the same page and that any adjustments or changes are reflected in a single source of truth. What’s more, centralizing this information means that changes can trigger other automation that helps with scheduling, ordering, and communications, which leads to an in-tune and efficient operation.

#2. Inventory control

Supply chain management is a critical part of the manufacturing process. As we have seen in recent years, any delays or mishaps can have a cascading effect that leads to product shortages that increase the price of goods. When this occurs industry-wide, consumers can absorb the costs. However, if it happens to one manufacturer, competitors can easily get a jump on your business because of lower prices.

As such, good inventory control is essential. RPA can assist with the three core elements of inventory control: monitoring inventory levels, communicating stock level alerts, and automating inventory reorders.

RPA tools help organizations build applications that give a holistic overview of their inventory and stay on top of potential delays. The end result is a more efficient system with fewer costly delays.

#3. Vendor communication

As the production of goods has become more specialized, manufacturing companies have become highly reliant on other vendors. Sourcing these specialized parts and components is a critical element of a successful supply chain, with communication essential for building and maintaining good relationships with vendors.

RPA tools can help automate communications with other vendors and ensure information sharing, inquiries, manufacturing status, and deliveries are easy to track across a wide range of systems. What’s more, it can ensure timely payments that boost trust.

#4. Predicting supply chain demand

The price of raw materials has steadily risen over the last few years. However, these prices are in a constant state of flux. RPA is already used by many businesses in different sectors for price monitoring, and manufacturing teams can apply the same principles for purchasing raw materials and other commodities.

Manufacturing procurement teams can use ML-powered RPA solutions to predict demand for their products and monitor commodity prices to execute transactions at opportune times. These processes can ensure goods are purchased at the lowest cost and improve profitability.

#5. Creating purchase orders

Manual purchase order (PO) creation is time-consuming and subject to human error. In busy manufacturing environments, the volume of these transactions is very high and often split across departments, with approval needed by someone in the finance team. Repetitive, high-volume tasks that are prone to human error? Sounds like a job for RPA.

RPA solves the problems associated with purchase orders by helping teams order goods, automating approvals via AI or notifying a decision maker, and forwarding the orders to the relevant parties. It can also monitor stock levels and automate orders, saving even more time.

#6. Invoice processing

Manufacturing businesses use a complex web of suppliers, often operating across international lines. As invoices flow into the business, authorization and approval are required from different teams. In addition, invoices can be received in different languages, adding a layer of complication.

RPA with Optical Character Recognition (OCR) can help teams read and understand emails and written invoices, enter the data into financial systems, notify the relevant approval officers, and process the transactions. Quick, accurate payments can vastly improve vendor relations and qualify teams for early payment discounts. The result is a smooth operation and better visibility into spending across the organization.

#7. Logistics tracking

Busy manufacturing teams can receive thousands of orders per month. RPA can help process and fulfil these orders by automating the entire process. However, once the goods leave the plant, there is more work to be done.

RPA can help manufacturing teams track shipments and provide their customers with delivery forecasts, updates about delays, and other critical information. RPA can also be employed to choose the quickest or cheapest shipping lanes ahead of time to ensure customer satisfaction.

#8. ERP integration

Large manufacturing operations often rely on Enterprise Resource Management (ERP) software to centralize their financial, warehousing, and customer success operations. These solutions are expensive to implement and maintain. What’s more, extending their abilities requires custom software development that is resource-heavy.

RPA tools provide an easy way to augment ERP software and extend their abilities with AI and ML capabilities. Much in the same way that RPA can expand legacy systems to fit around new requirements, RPA tools can operate with ERP tools to ensure that software fits custom needs.

#9. Regulatory compliance

Manufacturing organizations are under considerable pressure to meet compliance with health and safety, risk management, and production standards. These regulations are constantly changing and evolving and are subject to frequent audits to ensure compliance.

RPA bots help manufacturing teams run and provide rock-solid audits across their entire workflows. Additionally, they assist organizations with staying on top of shifting regulatory requirements and communicating updates to relevant teams. By keeping exhaustive records and data, manufacturers can run analyses of manufacturing procedures and intervene in processes before they become a problem.

RPA automation in the manufacturing

industry: Case studies

Manufacturing and production RPA case studies are among the best ways to highlight the ability of the technology to change and improve the sector.

#1. RPA for manufacturing accounts payable

A leading UK manufacturer had nine full-time staff operating their accounts payable department. The staff were split across five different business functions and were using legacy software with minimal interoperability. The problems were obvious: poor resource allocation and data visibility and considerable human errors, such as invoice duplication.

The team used an RPA solution to automate accounts payable, employing OCR to analyze invoices and centralize data collection. The business reduced human labor spent on invoices by 90%, slashed costs by 60%, and benefited from weekly reports that allowed great visibility of company performance. Read more here.

#2. Back office efficiencies

A high-end manufacturing plant faced shrinking revenues due to high levels of competition. Management audited existing processes and concluded that excessive time-to-market was the most significant cause of their issues. While the team had highly skilled staff, they were being pulled in various directions to deal with repetitive and mundane tasks that were far from an optimal use of their time.

The team looked at tasks like purchase orders, invoice reconciliation, and contract compliance and reasoned that many of these duties could be outsourced to a digital workforce of RPA bots. After automating over 20 business processes, the manufacturing team was free to perform their core duties, which led to quicker output and a 40% reduction in costs. Read more here.

#3. Dealing with manufacturing specifications

A multinational electronic manufacturer was making electrical switchboards for domestic and industrial use. The switchboards were assembled within the factory and pre-wired based on specifications. Manufacturing specifications needed to be printed alongside labels to highlight the positions of electrical circuits and circuit breakers.

Preparing the documents for the operators who installed the switchboards across customer sites was time-intensive and subject to human error. The company employed an RPA bot to read and understand the requirements and print out the relevant materials. This implementation meant that two staff members were able to rotate into value-driven tasks, ensuring increased productivity for the organization.

#4. Freight and logistics automation

A global player in the automotive industry was dealing with a high volume of overseas exports. One of the intricacies of these orders included the requirement for a Shipper’s Letter of Instruction (SLI) for the third-party freight forwarding company. The automotive company initially processed these letters manually, which took a lot of time and was subject to human error.

To make matters worse for the team, the order levels fluctuated wildly. Producing an SIL was a severe bottleneck for the business, which caused delays on the receiving end. The variance within requirements was another issue, with import and export laws changing according to jurisdiction.

The business implemented an RPA solution that periodically scanned incoming emails and determined which orders needed an SIL number. The bot extracted the orders, checked business rules against the ERP system, and determined which custom laws applied. From there, the correct SLI was forwarded to the freight company and the customer rep, saving endless time and confusion.

#5. Reducing business processes

A large Middle Eastern water purification and manufacturing plant with an established regional network was struggling with competition and high costs. With a 24-7 production pipeline, they needed to ensure greater data availability plus quality checks to get better visibility of their process and effect improvements.

After requirements analysis, the business identified five core areas where RPA could enhance productivity and save time. These processes included data entry, invoicing, production planning, and payroll. By implementing an RPA solution for these processes, the team eliminated human error, reduced human input by 90%, and saved an incredible 95% on costs. Read more here.

RPA automation in the

manufacturing industry: Benefits

As the case studies and use cases above show, RPA can make a huge impact in the manufacturing space. Here are some of the benefits of automated production and manufacturing processes that businesses can unlock to improve their operations.

#1. Lower overheads

Manufacturing, like most sectors, is under pressure to reduce overheads and deliver value for consumers. RPA tools are built to automate costly manual processes without compromising on quality.

One of the main areas where RPA saves on overheads is manual labor. The big benefit here is that RPA is hugely flexible and appropriate for a vast range of business processes across different departments. Procurement, accounts payables and receivables, warehousing and logistics, quality assurance, and even customer service can make use of RPA and drive down costs.

#2. Less human error

Human error is inevitable in the workplace. Tedious and repetitive tasks are often the source of these errors because employees are less engaged and often on “auto-pilot” as they work through these duties. RPA bots don’t suffer from the same problems because they faithfully execute tasks with a high level of precision and accuracy.

In high-volume manufacturing situations, human error can cost money, reputation, and, in the worst-case scenario, workers’ lives. Employing RPA can reduce these problems dramatically, with the additional bonus of boosting employee satisfaction.

#3. Increased productivity

RPA bots can work around the clock, 365 days a year. This advantage can help revolutionize production environments by outsourcing processes to a digital workforce with minimal human supervision.

Manufacturing teams must be capable of responding to fluctuating market demands. RPA helps organizations scale quickly and efficiently without the need to add human labor to their workforce.

#4. Improved quality control

Quality control is a vital part of any manufacturing operation. While physical machines are known for their precision, things can and do go wrong on the shop floor. Being able to identify and remedy these manufacturing errors is critical to reducing waste and boosting profits.

Real-time monitoring of production machines produces lots of data. RPA, assisted by ML, can help analyze this data and predict defects, leading to vastly improved quality control.

#5. Reduced environmental impact

In the point above, we talked about reducing waste in the manufacturing product. These advances will help with resource use and ensure teams can maximize raw materials. However, there are other environmental and sustainability advantages to consider, too.

RPA can help teams reduce energy use through smart energy and lighting allocation. It can also provide support and analysis to help businesses achieve ESG goals.

#6. Reducing parts proliferation

Parts proliferation is an endemic issue in the manufacturing industry. Manufacturing teams need to deal with a lot of parts, both made in-house and outsourced from other manufacturers. The situation occurs when engineers design new products and, specifically, the production of new parts despite suitable alternatives existing on the market.

The fallout is that there are several parts that are different yet perform the same function. The effect can lead to complex aftermarket care, reputation damage, and waste. RPA, alongside Cognitive AI, helps reduce this issue and leads to greater efficiency and resource use, saving untold millions across the manufacturing sector. Read this Deloitte report for more.

#7. Solve labor shortages

The Manufacturing Institute (MI) suggests that there will be over 2 million unfulfilled positions in the manufacturing industry by 2030. The present-day situation in the UK is not much better, with estimates suggesting that 36% of jobs are classed as hard-to-fill.

RPA, powered by ML and AI, can fill many of these positions and augment existing staff. With the right investment, manufacturing management teams can ensure that delays caused by understaffing are a thing of the past while ensuring their productivity and efficiency grows as more processes are automated.

RPA automation in the

manufacturing industry: Challenges

It’s a curious point of note that despite the manufacturing sector’s near-universal use of robotics in manufacturing, it has not led to a similar uptake in RPA. While statistics show that around 43% of manufacturing teams have adopted RPA solutions, there is room to grow to similar levels of automation machinery manufacturing.

Here, we will explore some of the challenges that face RPA adoption within the sector and how they may be solved.

#1. Domain expertise

While management in manufacturing may recognize the desperate need to unlock the benefits of RPA, they might not have the knowledge or expertise required to implement the solutions. The most effective implementation of RPA involves buy-in from several different departments and an understanding of how each team can coordinate around a solution.

ZAPTEST Enterprise customers can avail of a dedicated ZAP Expert to manage and design their RPA implementation, from requirements gathering all the way to using the product. Leaning on our expertise means that you don’t need to rely on your average manufacturer’s automation knowledge to embrace the tech.

#2. RPA limitations

RPA handles repetitive, rule-based tasks with organizations. However, there are plenty of tasks that are less suitable for RPA, such as processing unstructured data or mimicking human decision-making. However, when augmented by AI, Cognitive RPA can perform a blend of human and computer tasks, widening the scope of possible benefits within the manufacturing sector.

#3. Compliance

Manufacturing is subject to consistently evolving compliance standards. With rules and regulations changing all the time across different regions, many international manufacturers believe that it would be too difficult to manage a digital workforce that can respond to these demands. However, these scenarios are easily navigable by RPA because of its ability to be trained quickly by watching human workers.

#4. Outdated practices

While digital transformation successfully changed many industries over the last decades, many manufacturing sites still rely on manual processes and even pen and paper operations. Indeed, printed documentation is still a legal requirement for many manufacturing teams.

However, meeting these obligations shouldn’t come at the cost of digitizing work and generating data that can improve and optimize operations. RPA can help teams work in both formats.

#5. Legacy systems

Many manufacturing plants use state-of-the-art technology to run their machines but lack the same sophistication for back-end processes. In fact, legacy systems are still surprisingly common within the industry. Dragging these outdated systems into the present day is seen as a huge task that will result in expenses and downtime. However, RPA is adept at bridging the gap between legacy systems and modern infrastructure.

The future of RPA in the manufacturing sector

It’s fascinating to think how RPA could change the manufacturing sector in the future to deliver better products at lower costs.

One high-potential area to consider is raw materials purchase. AI and Machine Learning (ML) tools can crunch huge data sets, including historical price data and other factors, to forecast global demand. When paired with price monitoring tools, just-in-time practices, and supply chain efficiency, these machines could predict optimal purchasing times and lower resulting production costs.

Another big area where AI-assisted RPA tools can thrive is predictive maintenance. Machine downtime is the enemy of productivity, and sophisticated algorithms could use a variety of signals to predict and schedule maintenance so that the work does not halt productivity.

Computer Vision Technology (CVT) and sensors will also be employed in the manufacturing sector to ensure a higher level of product quality assurance, and lead to lower waste.

Industry 4.0 in the manufacturing sector

Industry 4.0 refers to the next stage of human production. It involves the use of tools like cloud computing, AI, ML, data analytics, IoT, and sensor technology to create smart factories that are capable of running with minimal human intervention.

Hyperautomation, the philosophy of automating all possible processes within an organization, will be part of Industry 4.0. Intelligent Automation will help manufacturers unlock a new level of efficiency across their departments to create an always-on and constantly improving centralized system that mines business processes and automates solutions to drive automated production.

A significant element of this process will involve the creation of new, customized software, often coded by computers or prompt engineering and verified by test automation tools.

Paired with other Industry 4.0 technologies, factories will become capable of flexible and customizable manufacturing that balances current market demands with predictive production of other goods and services.

Final thoughts

There are endless practical benefits of RPA automation in the manufacturing industry. From managing supply chains to handling back-office tasks to answering the shortage of skilled workers, RPA is a solution for many of the biggest challenges facing manufacturers today.

However, beyond solving short-term problems, factory RPA automation can help manufacturers adjust to the future by using cutting-edge AI tools. Manufacturing is a competitive space. Faster time-to-market, lower costs, and less waste are benefits that executives can’t ignore.

Manufacturing and automation have strong associations already. However, if manufacturers want to move into the future, they need to adopt RPA solutions before they get left behind.